Part 1 Sail Dynamics:The Concept of Automatic rigs

Part 1 The Concept

1.0 Introduction

The winds we sail in are unsteady, and vary not only from hour to hour and minute to minute but second by second. These changes occur too quickly for a crew to reconfigure the sail settings, and an ideal rig will alter automatically to suit these rapid changes. There are two different aspects to an “automatic rig.”

(a) Below the design wind flexibility to adjust to micro and macro wind speed changes in such a way as to maximise acceleration and minimise increases in side force. In simple terms this means the upper leech falls off a controlled amount due to increased wind strength and apparent wind angle in gusts and vice versa.

(b) At and above the design wind to flatten and feather the sail, especially the upper parts, to minimise drag and heeling moment. Flapping must be avoided.

The design wind is fairly well set in dinghies where the maximum heeling moment occurs close to no heel, but is rather less well defined for non-canting keel yachts and can vary from around 15 degrees for light flat boats up to more for thinner ones. For an IOM it is probably about 25 to 30 degrees or so.

The first time I experienced this was in the NS14 class: the difference was astonishing both for the ease of sailing but also the speed advantage, with gains of 4 to 5 minutes round a 90 minute course, even though our thinking was not this far advanced.

2.0 How is it done?

The primary tools that designers have to achieve this automatic response are:

1) Mast flexibility and its distribution.

2) Rigging flexibility

3) Sail cloth stiffness.

4) Plan shape of the sail (large roaches and stiff battens up high help, especially with (a) above).

5) Sail cloth stiffness

6) Batten stiffness (full length battens)

7) Sail structure (if camber is put in by seam taper rather than by luff round the leech stands up better.)

8) Prestress of the sail, rigging tension and mast bend at setup.

In all cases the driver for auto response is the wind induced changes in the leech tension of headsail and main. To evoke (b) above this needs some form of prestress so that the sudden change occurs at a predetermined wind speed. The elastic response (a) should not be overdone otherwise too much power can be shed.

Rigs that behave like this are now used in many dinghy and even yacht classes. Bethwaite (1996) describes the system used in the B18 class: this had a mast that was shaped and rigged to be rigid below the hounds and relatively floppy above. By using a very high luff tension on the main, the mast was prebent so when the wind increased to the design wind strength, the increased luff tension became enough to make mast bent further and the sail feathered.

There are now numerical modelling programs used for large yacht design, and the buzz word for this is aero-elasticity, however for one set of runs you could buy a fleet of IOMs and I am not sure if the algorithms are right for air and water flow at the scale of model yachts, so approximate calculation and testing are a more realistic bet.

With this background I set out to find how model yacht rigs stack up, especially the IOM class.

Some class rules mean that the choice is restricted. For instance in the IOM class the mast has to be uniform for the full height and the sail plan shape is tightly controlled. In model yachts there is not a lot of choice for sail materials and most are rather stiff relative to full size sails.

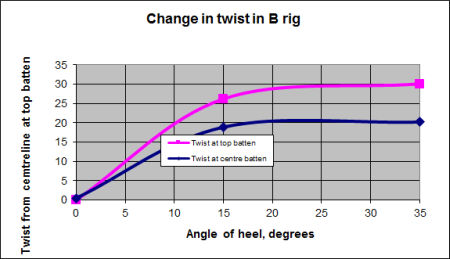

As a first look at an IOM rig I used an early apparatus as in the picture, and did a set of tests on a B rig that could later be quantified. Results for twist in the mainsail at the upper and middle battens are shown in the chart for an apparent wind angle of about 40 degrees and a backstay tension of 25N.

The lower axis is the amount of heel caused by the wind speed when the readings were taken. The numbers at zero heel were obtained inside with the mast horizontal so only the weight of the sail cloth pulled the sail down. It can be seen that initially the twist changed rapidly with heel angle, with this process certainly completed by a heeled angle of 15 degrees, and maybe before that. This change is probably due to the different distribution of wind pressure, which tends toward a quadrilateral shape across the chord with a maximum near the mast, as compared to the cloth weight which is uniform across the chord.

Beyond 15 degrees of heel the twist changed only a little, less than one might hope for in an automatic rig. The camber hardly changed at all over this range and the sail stubbornly held its camber in spite of increasing wind pressure and clearly showed no ability to adjust to wind change without intervention, rather like the old telegraph pole rigs we had on dinghies before the mid 1960’s when we began to work on “automatic” rigs.

This does seem to be changing in the IOM Class, but is not widespread.

The following parts in this series describe some tests and analyses on this topic.

Reference

Bethwaite (1996) High Performance Sailing

Colin Thorne March 2013

Rigs & Sails

Rigs & Sails